From Sample to Bulk: How to Ensure Consistency in Sportswear Production

- Share

- publisher

- sunny

- Issue Time

- Oct 31,2025

Summary

Speed means nothing without consistency. This article explores how top sportswear manufacturers ensure perfect alignment between samples and bulk production—through digital pattern systems, MES tracking, and precision quality control.

1. Why Sample-to-Bulk Consistency Defines Brand Trust

For sportswear brands, the sample is the promise—and bulk production is the proof. Many brands experience the same frustration: the approved sample looks perfect, but the bulk shipment differs in fit, fabric tension, or stitching quality.

Such inconsistencies not only waste time and money but also damage consumer trust. That's why top-tier manufacturers now use digital and data-driven systems to guarantee precise replication between sample and production.

The true sign of a professional factory is not how fast they produce—but how precisely they repeat.

2. The 3 Core Challenges in Maintaining Consistency

| Challenge | What Can Go Wrong | Result |

| Fabric Variation | Different dye batches or GSM fluctuations | Uneven texture and fit |

Pattern Distortion | Manual grading errors | Size inconsistency across styles |

Process Control | Lack of QC checkpoints | Quality variation between batches |

These problems are avoidable—with the right systems and controls. | ||

3. HUCAI's Proven Process to Ensure 99% Consistency

HUCAI Garment Co., Ltd. has built a complete digital sample-to-bulk system combining pattern accuracy, fabric verification, and smart production monitoring.

1️⃣ Digital Pattern & Grading System

Every pattern is created using 3D CAD technology and stored in HUCAI's digital library.

- Prevents manual measurement errors

- Enables quick resizing for different fits

- Ensures identical cutting templates for all orders

Result: 99% consistency between prototype and production.

2️⃣ Fabric Pre-Testing & Approval

Each fabric batch undergoes:

- Shrinkage testing (below 5%)

- Color fastness testing (Grade 3+ standard)

- Elastic recovery and durability checks

These tests ensure that the same fabric behavior is replicated in every batch, avoiding fit or color deviation.

3️⃣ Smart MES Production Tracking

HUCAI's MES (Manufacturing Execution System) links sample orders and bulk lines through digital tracking:

- Operators scan pattern barcodes for accuracy

- Cutting, sewing, and finishing stages are recorded in real-time

- Deviations trigger automatic alerts for rechecking

This guarantees every bulk piece follows the exact sample workflow.

4️⃣ Multi-Level Quality Control

HUCAI enforces a 4-level QC system across the production chain:

1. Fabric inspection before cutting

2. In-line QC during sewing

3. Final AQL 2.5 inspection

4. Random re-check by supervisors before packing

The process ensures no deviation slips through unnoticed.

5️⃣ Sample Retention for Reference

Each approved sample is archived and tagged in HUCAI's sample room. Before bulk cutting, QC teams compare measurements and seam details to confirm 100% alignment.

4. Why Digital Accuracy Equals Brand Efficiency

Digitalization transforms sample replication from guesswork into precision science. With HUCAI's systems in place, brands benefit from:

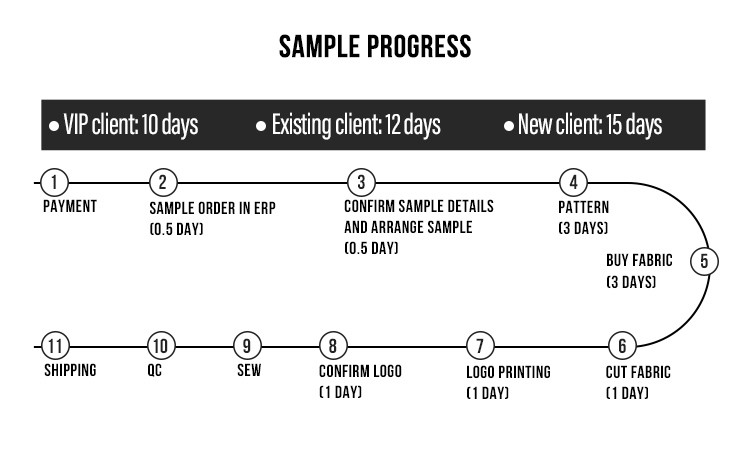

- Faster approval cycles (samples ready in 12 days)

- Reduced remake or waste cost

- Stronger confidence for repeat collections

- Reliable bulk quality for online and retail sales

Consistency is not a one-time achievement—it's a process of control, verification, and continuous refinement.

5. HUCAI's Sample-to-Bulk Workflow Overview

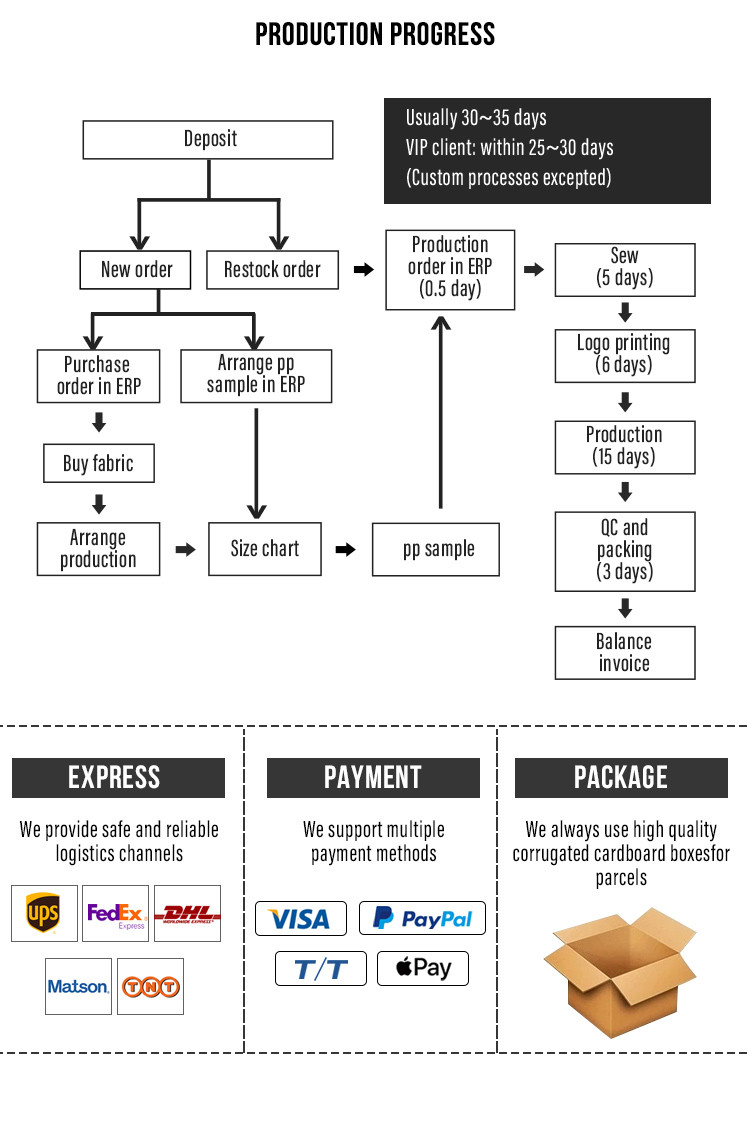

| Stage | Key Actions | Technology Used |

| Design Input | Receive client tech packs or select from ODM library | ERP system integration |

| Pattern Creation | Digital CAD & 3D simulation | Digital pattern system |

| Fabric Testing | Shrinkage, color fastness, GSM check | Lab test equipment |

Sample Approval | Fit, color, workmanship review | Sample retention system |

Bulk Production | MES-guided process + 4-level QC | Smart production lines |

Final Inspection | AQL 2.5, color & measurement match | Digital QC dashboard |

6. Why Brands Choose HUCAI

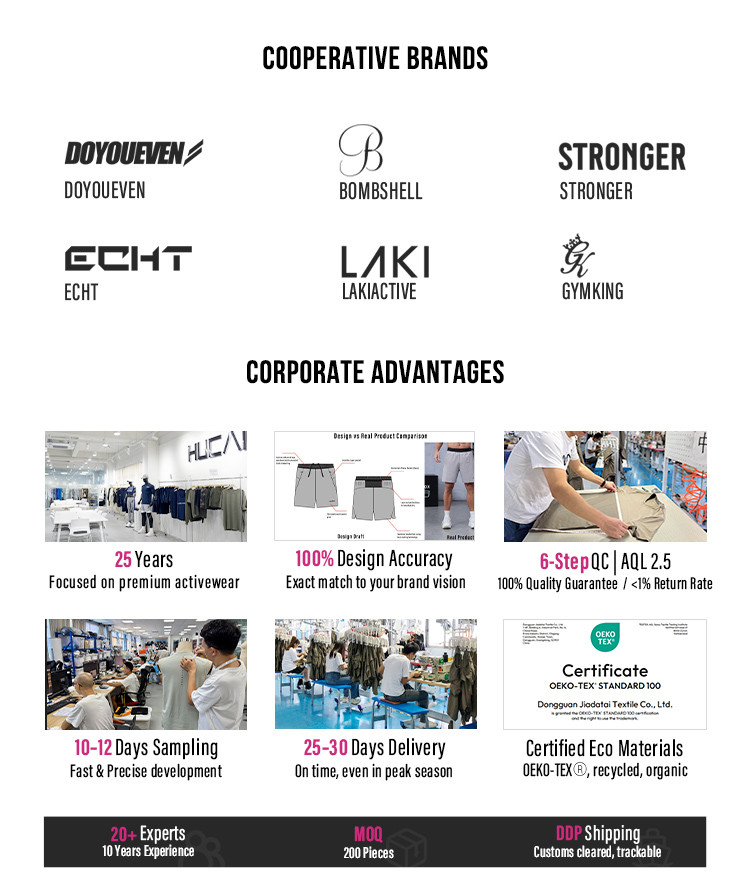

HUCAI's dedication to precision and reliability has earned the trust of global premium fitness and yoga brands.

Key advantages:

- 12-day sampling & 25–30-day bulk turnaround

- 99% pattern and fit consistency

- MES & ERP integrated production management

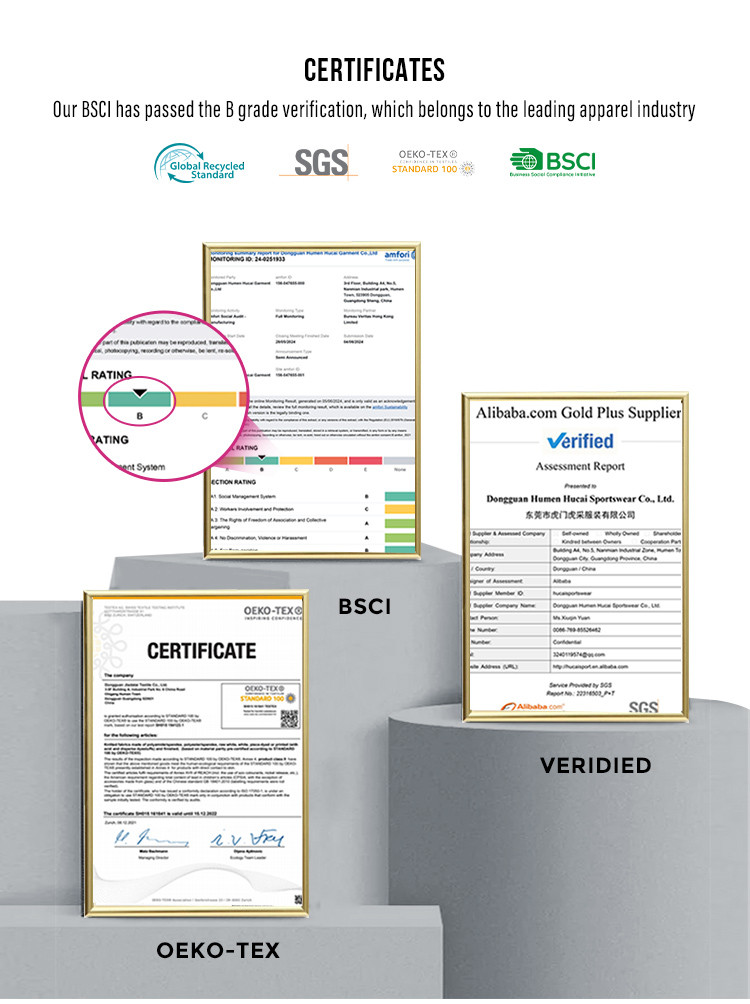

- Certified with BSCI, WRAP, OEKO-TEX®, GRS, Disney FAMA

- In-house design & pattern development team

HUCAI turns sample approval into long-term manufacturing confidence.

7. Precision Is the New Speed

In the fast-moving sportswear industry, success belongs to brands that balance speed with reliability. Perfect sample-to-bulk consistency doesn't just improve efficiency—it builds lasting trust with your customers.